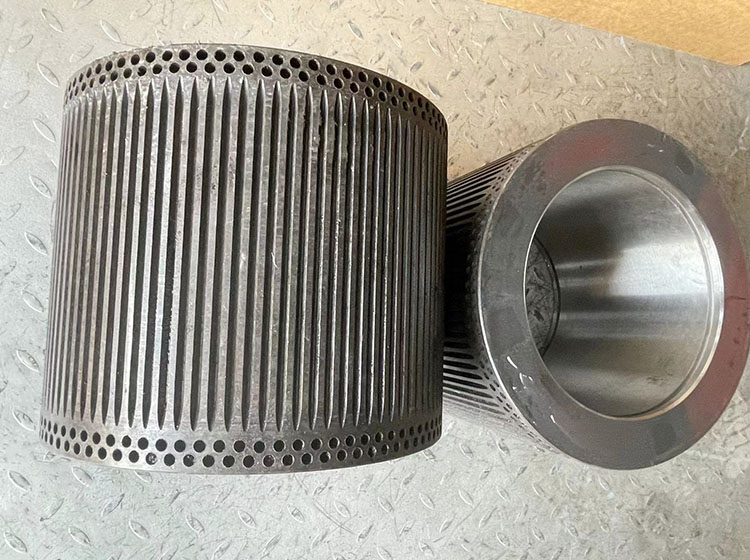

Biyu Hakora Roller Shell

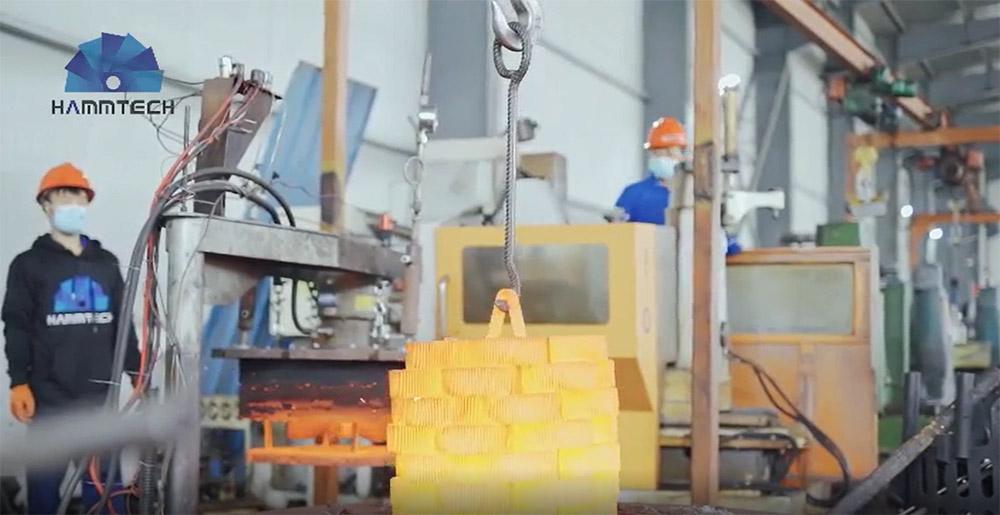

Harsashin niƙa na pellet shine muhimmin kayan haɗi na pelletizer, wanda kuma yana da sauƙin sawa yayin da zobe ya mutu. Yana aiki musamman tare da zobe mutu da lebur mutu don yanke, knead, saita, da matse da albarkatun kasa don cimma pelletizing. Ana amfani da bawo mai yadu don sarrafa pellet ɗin abinci na dabba, pellet ɗin mai biomass, da sauransu.

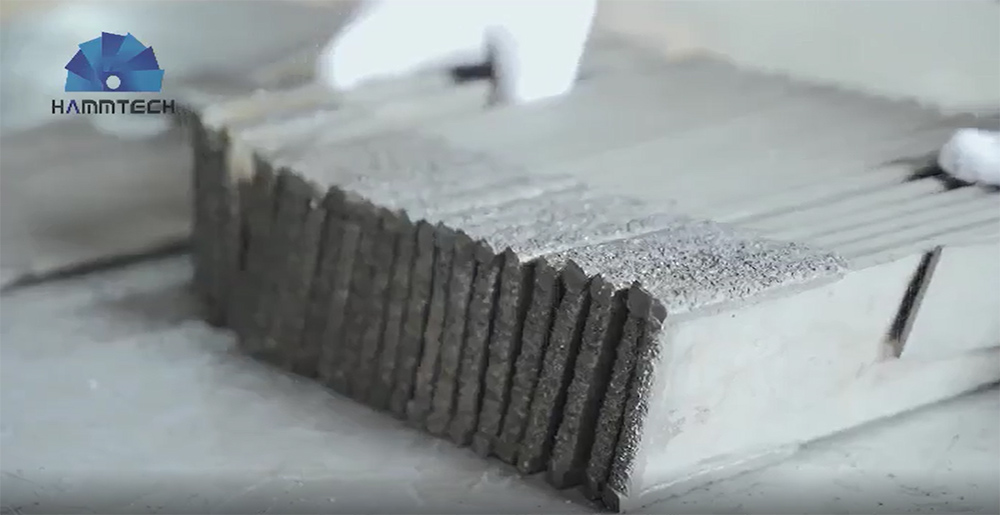

A cikin tsari na granulator, don tabbatar da cewa za a iya danna albarkatun kasa a cikin rami mai mutu, dole ne a sami wasu rikice-rikice tsakanin harsashi da kayan aiki, don haka lokacin yin abin nadi, za a tsara shi da nau'i daban-daban na m saman don hana abin nadi daga zamewa. Akwai nau'ikan filaye guda uku waɗanda aka fi amfani da su: nau'in dimple, nau'in buɗaɗɗe, da nau'in rufewa.

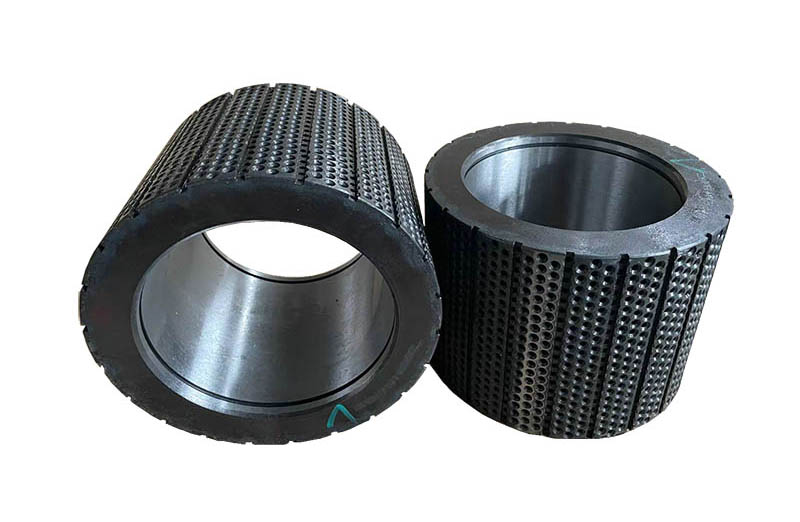

Girman Roller Shell

Fuskar harsashin abin nadi da aka yi kamar saƙar zuma ne mai kogo. A cikin aiwatar da amfani, da rami cike da abu, forming wani gogayya surface coefficient ne karami, da abu ba sauki don zamewa a kaikaice, da lalacewa na zobe mutu na granulator ne mafi uniform, da kuma tsawon da barbashi samu ne mafi m, amma yi abu yi ne dan kadan muni, za a iya samun wani tasiri a kan yawan amfanin ƙasa na granulator, a cikin ainihin samar ba a matsayin na kowa kamar yadda rufe iri-iri.

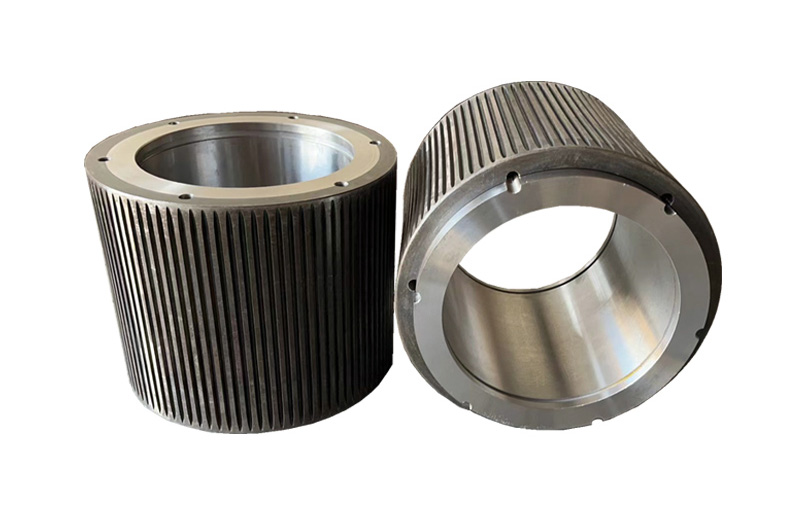

Ƙarshen Roller Shell

Yana da ƙarfin hana zamewa mai ƙarfi da kyakkyawan aikin kayan nadi. Koyaya, a cikin tsarin samarwa, kayan suna zamewa a cikin tsagi na hakori, wanda zai iya haifar da matsalar zamewar kayan zuwa gefe ɗaya, yana haifar da wani bambanci a cikin lalacewa na harsashi da zobe ya mutu. Gabaɗaya, lalacewa yana da tsanani a ƙarshen biyu na abin nadi da zobe ya mutu, wanda zai haifar da wahalar fitar da kayan a ƙarshen zobe biyu ya mutu na dogon lokaci, don haka pellet ɗin da aka yi sun fi guntu na tsakiyar zoben mutu.

Roller Shell mai rufewa

An ƙera ƙarshen wannan nau'in harsashi guda biyu don zama nau'in rufaffiyar (nau'in tsagi mai haƙori tare da gefuna da aka rufe). Saboda rufaffiyar gefuna a ɓangarorin biyu na tsagi, albarkatun ƙasa ba su sauƙi zamewa zuwa bangarorin biyu a ƙarƙashin extrusion, musamman idan aka yi amfani da su wajen fitar da kayan ruwa waɗanda suka fi saurin zamewa. Wannan yana rage wannan zamewa kuma yana haifar da ko da rarraba kayan, ƙarin yuwuwar lalacewa na harsashi da zobe suna mutu, don haka ƙarin daidaiton tsayin pellets.