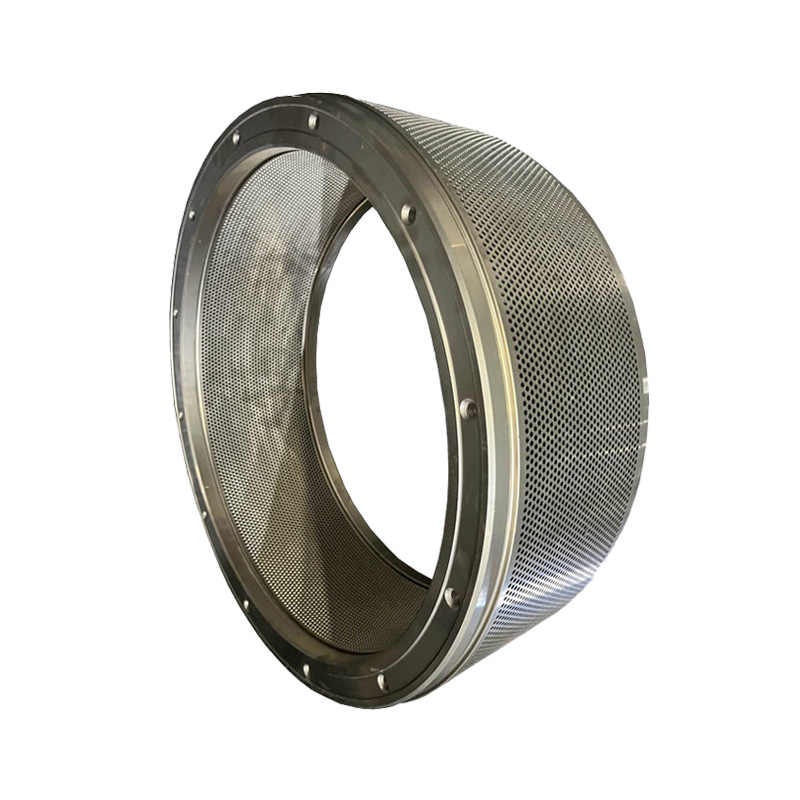

Ciyarwar Kifi Pellet Mill Ring Die

Domin sarrafa uniformity na taurin zobe mutu bayan zafi magani, bayan zafi magani na kowane zobe mutu, a cikin kowane bangare na kewaye shugabanci na uku daidai sassa, dauki ba kasa da 3 maki don auna matsakaicin darajar taurin. Bambanci tsakanin taurin kowane bangare bai kamata ya fi HRC4 girma ba.

Bugu da ƙari, ya kamata a kula da taurin ƙarancin zobe na zobe, kuma taurin ya kamata ya kasance tsakanin HB170 da 220. Idan taurin ya yi girma sosai, ƙuƙwalwar ƙuƙwalwar yana da sauƙi don karya kuma ya haifar da ramuka. Idan taurin ya yi ƙasa sosai, ƙarshen ramukan mutu zai shafi. Don sarrafa daidaitattun kayan da ke cikin blank, idan zai yiwu, kowane blank ya kamata a gudanar da bincike na ciki, don hana ɓarna na ciki, pores, yashi, da sauran lahani.

Roughness kuma wani muhimmin index ne don auna ingancin zobe mutu. A daidai wannan rabo na matsawa, mafi girman ƙimar rashin ƙarfi, mafi girman juriya ga extrusion kuma mafi wahalar fitar da abinci. Matsayin da ya dace ya kamata ya kasance tsakanin 0.8 da 1.6.

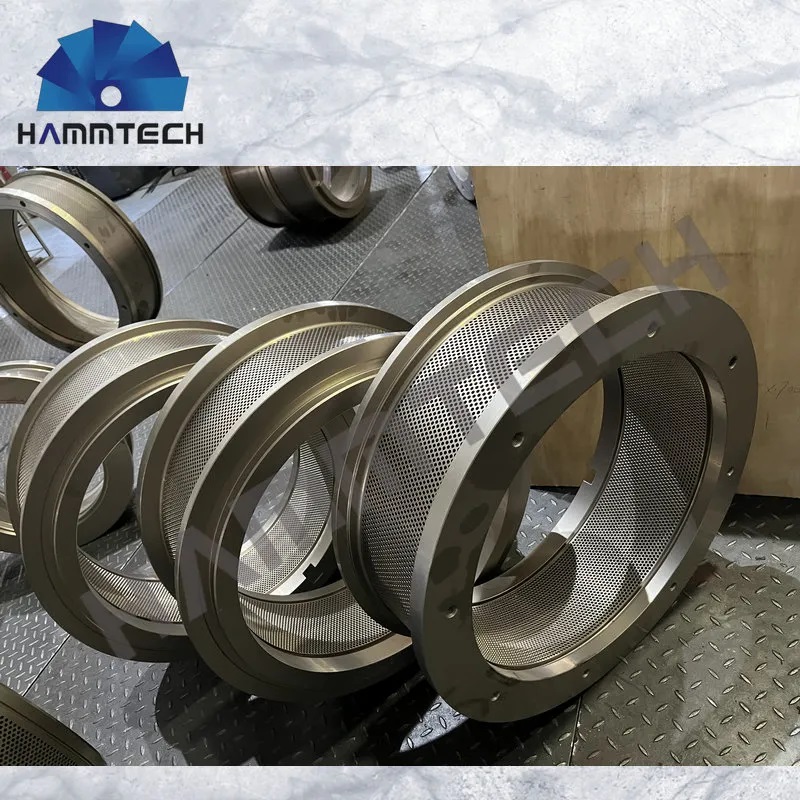

1. An nannade zobe a cikin fim din filastik mai hana ruwa.

2. Kunshin katako ko na musamman kamar yadda buƙatun abokan ciniki.

3. Daidaitaccen kunshin fitarwa wanda ya dace da sufuri mai nisa.

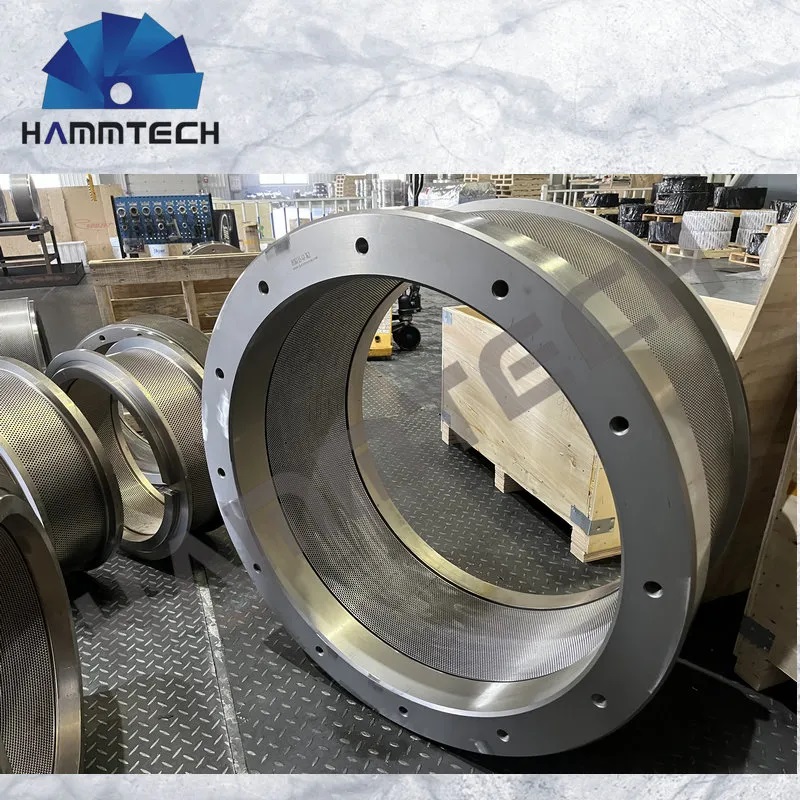

Tun daga 2006, HAMMTECH yana ba da ƙwararrun kayan aikin kayan abinci ga abokan ciniki a duk duniya.

HAMMTECH shine mai siyar da kayan haɗi na tsayawa ɗaya.

HAMMTECH yana hidimar abokan ciniki a cikin ƙasashe sama da 30.

Muna samar da nau'ikan samfura daban-daban don masana'antu daban-daban kamar injinan abinci na pellet, biomass pellet Mills, da na likitanci.