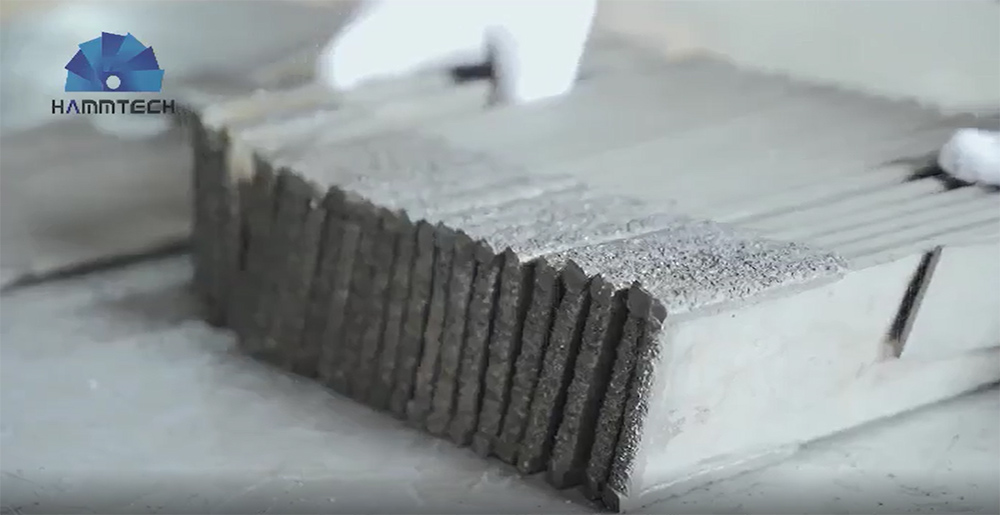

Helical Teeth Roller Shell

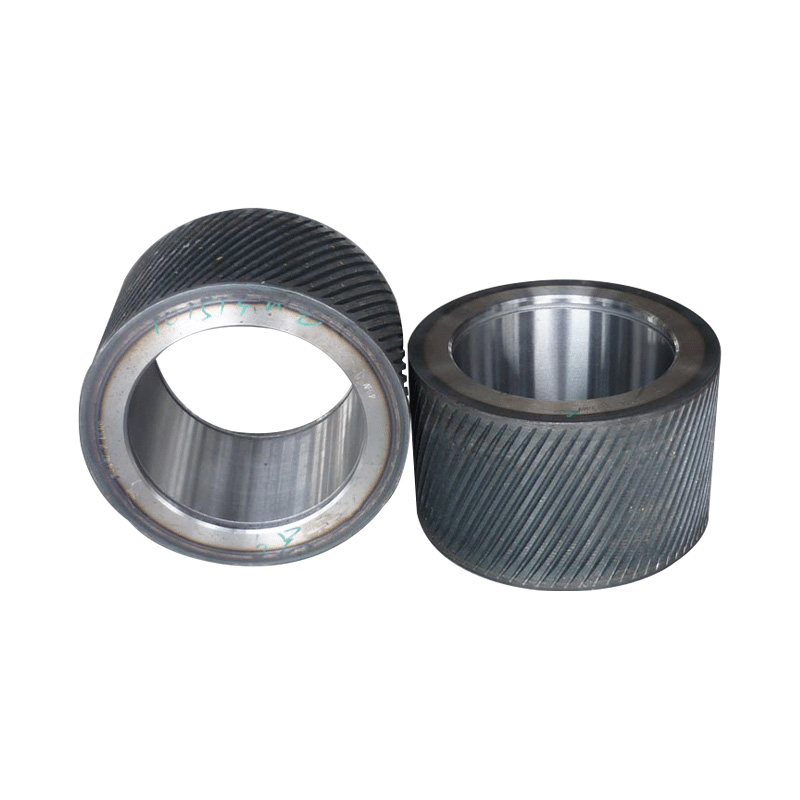

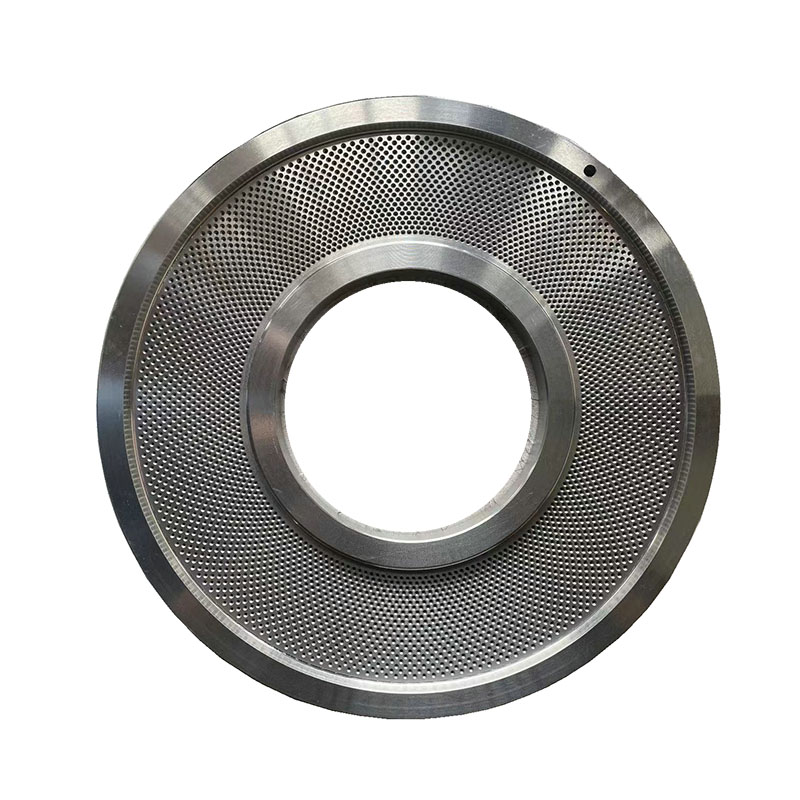

Me yasa yake da mahimmanci don daidaita rata tsakanin zoben injin pellet mutu da abin nadi?

Daidaita daidaitaccen ratar abin nadi shine muhimmin yanayi don cimma matsakaicin iya aiki da tsawaita rayuwar abin nadi da zobe ya mutu. Mafi dacewa tazara ga zobe mutu da abin nadi ne 0.1-0.3 mm. Lokacin da tazarar ta fi 0.3mm, Layer kayan yana da kauri da yawa kuma ba a rarraba shi ba, yana rage fitar da granulation. Lokacin da tazarar ta kasa da 0.1mm, injin yana sawa sosai. Gabaɗaya, yana da kyau a kunna na'ura kuma a daidaita abin nadi lokacin da baya juyawa ko kuma ɗaukar kayan da hannu kuma a jefa shi cikin injin ɗin don jin ƙarar ƙara.

Menene abubuwan da ke faruwa idan tazar ta yi ƙanƙanta ko babba?

Ƙananan ƙananan: 1. An jinkirta mutuwar zobe; 2. Nadi mai matsa lamba yana sawa sosai; 3. A lokuta masu tsanani, wannan na iya haifar da karyewar zobe ya mutu; 4. Jijjiga na granulator yana ƙaruwa.

Ya girma da yawa: 1. Tsarin zamewar abin nadi na matsa lamba ba ya samar da kayan; 2. Layer kayan cin abinci yana da kauri sosai, yana toshe injin akai-akai; 3. An rage ingancin granulator (mai masaukin granulation zai iya isa ga cikakken kaya a sauƙaƙe, amma ba za a iya ɗaukaka abinci ba).