Na'urar pellet na'ura ce don damfara man pellet na biomass da abincin pellet, daga cikinsu abin na'urar matsa lamba shine babban bangarensa da kuma sashinsa mai rauni. Saboda yawan aiki da yanayin aiki mai tsanani, ko da tare da inganci, lalacewa da tsagewa ba makawa. A cikin tsarin samarwa, yawan amfani da na'ura mai mahimmanci yana da girma, don haka kayan aiki da kayan aiki na kayan aiki na matsi suna da mahimmanci.

Binciken gazawar na'urar matsa lamba na injin barbashi

Tsarin samarwa na abin nadi na matsin lamba ya haɗa da: yankan, ƙirƙira, daidaitawa (annealing), machining mai ƙazanta, quenching da tempering, injin daidaitaccen mashin ɗin, quenching surface, da mashin daidaici. Ƙwararrun ƙwararrun ƙungiyar ta gudanar da bincike na gwaji game da lalacewa na ƙwayar pellet na biomass don samarwa da sarrafawa, samar da tushen ka'idar don zaɓin ma'ana na kayan abin nadi da hanyoyin magance zafi. Waɗannan su ne ƙarshen bincike da shawarwari:

Dents da karce suna bayyana a saman abin nadi na matsa lamba na granulator. Sakamakon lalacewa na ƙazanta masu tauri kamar yashi da filayen ƙarfe a kan abin nadi, yana da lahani mara kyau. Matsakaicin lalacewa na sama yana kusan 3mm, kuma lalacewa a bangarorin biyu ya bambanta. Yankin ciyarwa yana da mummunan lalacewa, tare da lalacewa na 4.2mm. Yafi saboda gaskiyar cewa bayan ciyarwa, homogenizer ba shi da lokaci don rarraba kayan a ko'ina kuma ya shiga tsarin extrusion.

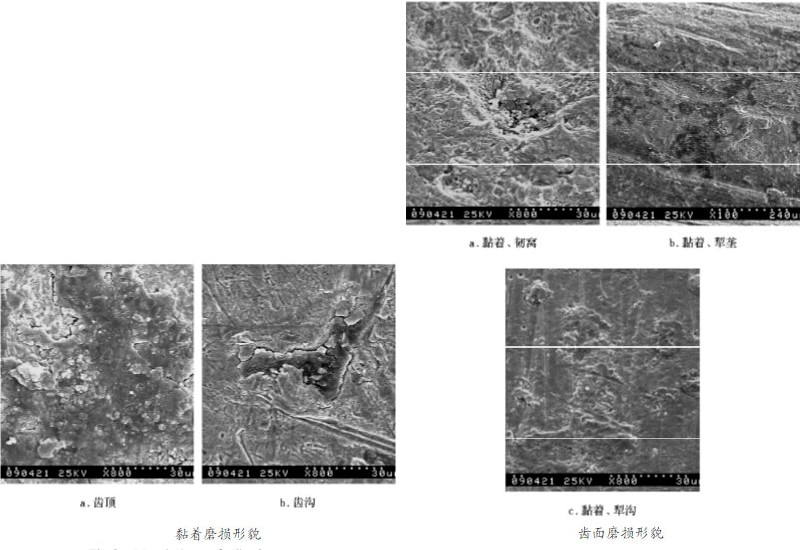

Binciken gazawar ƙananan ƙwayoyin cuta ya nuna cewa saboda raunin axial a kan saman abin nadi na matsa lamba da albarkatun ƙasa ke haifarwa, rashin abubuwan da ke kan abin nadi na matsa lamba shine babban dalilin gazawar. Babban nau'i na lalacewa shine lalacewa na mannewa da lalacewa, tare da ilimin halittar jiki irin su ramuka masu tauri, ramukan garma, ramukan garma, da dai sauransu, wanda ke nuna cewa silicates, ƙwayoyin yashi, filayen ƙarfe, da dai sauransu a cikin kayan albarkatun ƙasa suna da mummunar lalacewa a saman abin nadi na matsa lamba. Sakamakon aikin tururin ruwa da wasu dalilai, laka kamar alamu suna bayyana a saman abin nadi na matsin lamba, wanda ke haifar da fashewar damuwa a saman abin nadi.

Ana ba da shawarar ƙara tsarin kawar da ƙazanta kafin murkushe albarkatun ƙasa don cire ɓangarorin yashi, filayen ƙarfe, da sauran ƙazanta waɗanda aka gauraya a cikin kayan, don hana lalacewa da tsagewa a kan masu matsa lamba. Canja siffar ko matsayi na scraper don rarraba kayan a ko'ina a cikin ɗakin matsawa, hana rashin daidaituwa akan abin nadi da kuma ƙara lalacewa a saman abin nadi. Saboda gaskiyar cewa abin nadi na matsa lamba yafi kasawa saboda lalacewa ta sama, don haɓaka taurin samansa, juriya, da juriya na lalata, ya kamata a zaɓi kayan da ba za su iya jurewa da matakan kula da zafi masu dacewa ba.

Material da kuma tsarin jiyya na matsa lamba rollers

Abubuwan da ke tattare da kayan aiki da tsari na abin nadi na matsa lamba sune abubuwan da ake buƙata don ƙayyade juriyar lalacewa. Abubuwan nadi da aka saba amfani da su sun haɗa da C50, 20CrMnTi, da GCr15. Tsarin masana'antu yana amfani da kayan aikin injin CNC, kuma ana iya daidaita yanayin nadi tare da madaidaiciyar hakora, haƙoran haƙora, nau'ikan hakowa, da sauransu bisa ga buƙatu. Ana amfani da quenching na carburization ko magani mai zafi mai ƙarfi don rage nakasar abin naƙasa. Bayan maganin zafi, ana sake aiwatar da mashin ɗin daidaitaccen mashin don tabbatar da daidaituwar da'irori na ciki da na waje, wanda zai iya tsawaita rayuwar sabis na abin nadi.

Muhimmancin maganin zafi don matsa lamba rollers

Yin aikin nadi na matsa lamba dole ne ya dace da buƙatun ƙarfin ƙarfi, ƙarfin ƙarfi mai ƙarfi (juriya na sawa), da ƙarfi mai ƙarfi, gami da injina mai kyau (ciki har da gogewa mai kyau) da juriya na lalata. Maganin zafi na rollers wani muhimmin tsari ne wanda ke nufin ƙaddamar da yuwuwar kayan aiki da haɓaka aikin su. Yana da tasiri kai tsaye akan daidaiton masana'anta, ƙarfi, rayuwar sabis, da farashin masana'anta.

Don kayan abu ɗaya, kayan da aka yi amfani da maganin zafi suna da ƙarfi da ƙarfi, tauri, da dorewa idan aka kwatanta da kayan da ba a yi amfani da su ba. Idan ba a kashe ba, rayuwar sabis na abin nadi zai zama ya fi guntu sosai.

Idan kana so ka bambanta tsakanin sassan da aka yi da zafi da kuma wadanda ba a kula da zafi ba, wanda aka yi daidai da machining, ba zai yiwu ba a bambanta su kawai ta hanyar taurin launi da launi na maganin zafi. Idan baku son yankewa da gwadawa, zaku iya gwada su ta hanyar latsa sauti. Tsarin ƙarfe na ƙarfe da juzu'i na ciki na simintin gyare-gyare da ƙarewa da kayan aiki masu zafi sun bambanta, kuma ana iya bambanta su ta hanyar taɓawa a hankali.

An ƙayyade taurin maganin zafi da abubuwa da yawa, ciki har da darajar kayan aiki, girman, nauyin aiki, siffar da tsari, da hanyoyin sarrafawa na gaba. Misali, lokacin amfani da waya ta bazara don yin manyan sassa, saboda ainihin kauri na kayan aikin, littafin ya bayyana cewa taurin maganin zafi zai iya kaiwa 58-60HRC, wanda ba za a iya samu a hade tare da ainihin kayan aikin ba. Bugu da kari, alamomin taurin mara ma'ana, kamar tsananin taurin wuce kima, na iya haifar da asarar taurin aikin da haifar da fashe yayin amfani.

Maganin zafi ya kamata ba kawai tabbatar da ƙimar ƙarfin ƙarfi ba, amma kuma kula da zaɓin tsari da sarrafa tsari. Ƙunƙarar zafi mai zafi da zafi na iya cimma ƙarfin da ake buƙata; Hakazalika, a ƙarƙashin dumama yayin quenching, daidaita yanayin zafin jiki kuma na iya saduwa da kewayon taurin da ake buƙata.

The Baoke matsa lamba nadi da aka yi da high quality-karfe C50, tabbatar da taurin da kuma sa juriya na barbashi inji matsa lamba nadi daga tushen. Haɗe da fasaha mai zafi mai zafi mai kashe zafi, yana faɗaɗa rayuwar sabis ɗin sa sosai.

Lokacin aikawa: Juni-17-2024