A cikin granulation masana'antu, ko yana da lebur mutu pellet inji ko zobe mutu pellet inji, da aiki ka'idar shi ne dogara da dangi motsi tsakanin matsa lamba rollershell da mold ansu rubuce-rubucen da kayan da shigar da tasiri tashar, extrude shi a cikin siffar, sa'an nan a yanka a cikin barbashi na tsawon da ake bukata da yankan ruwa.

Barbashi danna abin nadi

Harsashin abin nadi na matsin lamba ya haɗa da madaidaicin madaidaicin madauri, mirgine bearings, matsi na abin nadi hannun riga a wajen matsi na abin nadi, da kuma abubuwan da aka yi amfani da su don tallafawa da gyara harsashin abin nadi.

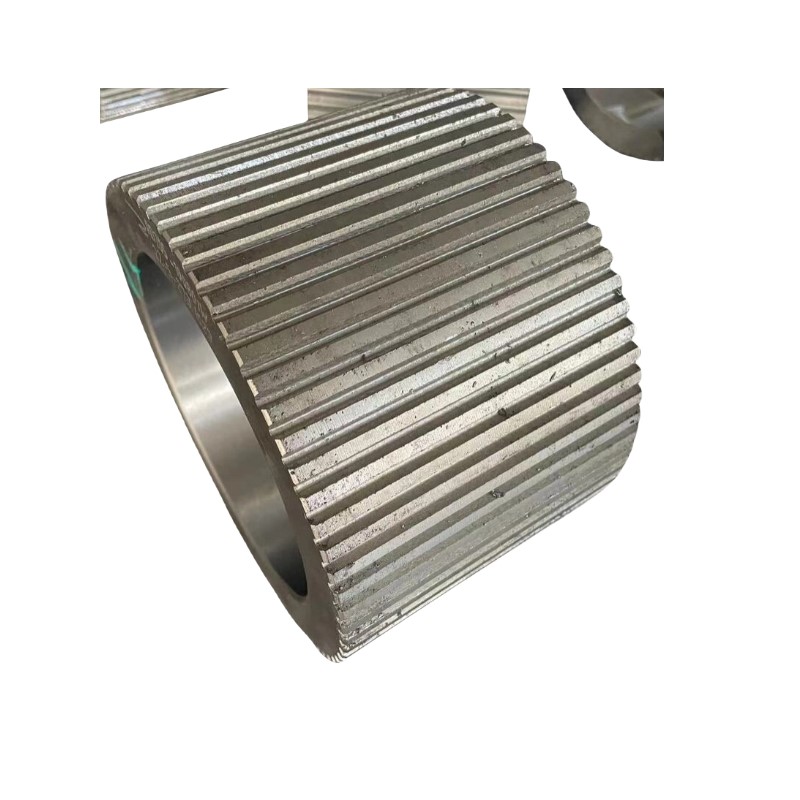

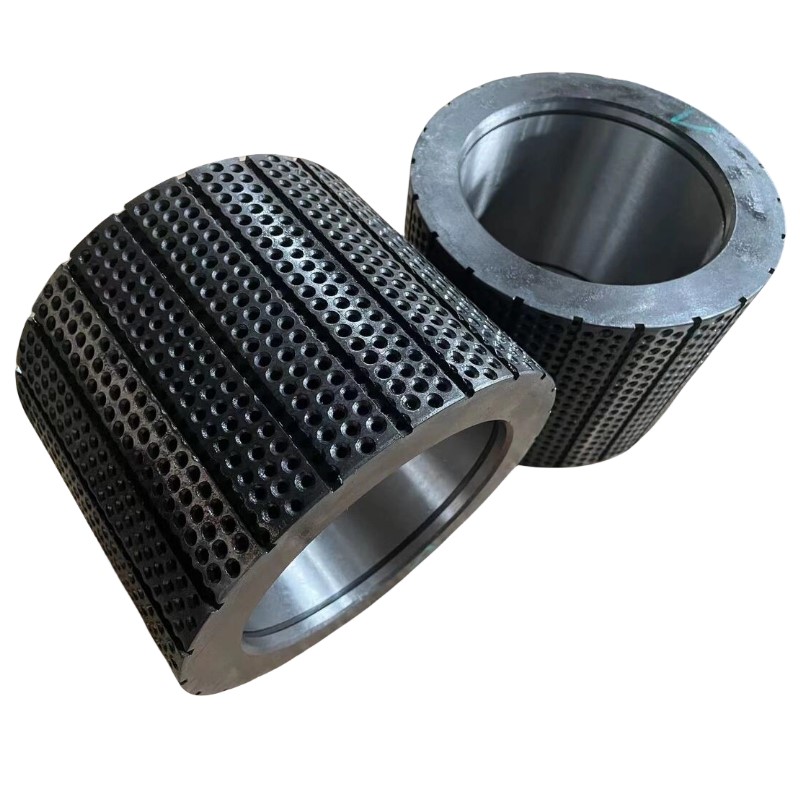

Matsakaicin rollershell yana matse kayan a cikin ramin ƙira kuma ya samar da shi ƙarƙashin matsin lamba a cikin ramin ƙira. Don hana abin nadi na matsa lamba daga zamewa da kuma ƙara ƙarfin kamawa, dole ne a sami takamaiman ƙarfin juzu'i tsakanin abin nadi da kayan. Don haka, ana ɗaukar matakan ƙara juriya da juriya akan saman abin nadi. Lokacin da aka ƙayyade sigogi na tsarin nadi da mold, tsarin tsari da girman girman farfajiyar waje na abin nadi yana da tasiri mai mahimmanci akan ingancin granulation da ingancin barbashi.

Tsarin saman matsi na abin nadi harsashi

Akwai nau'ikan nau'ikan saman guda uku don abubuwan da ke akwai na latsawa na abin nadi: tsattsauran abin nadi, saman abin nadi tare da rufe baki, da saman abin nadi na saƙar zuma.

Nau'in matsa lamba mai haƙori yana da kyakkyawan aikin mirgina kuma ana amfani dashi sosai a masana'antar ciyar da dabbobi da kaji. Duk da haka, saboda zamewar abinci a cikin tsagi mai haƙori, lalacewa na abin nadi da ƙirar zobe ba daidai ba ne, kuma lalacewa a ƙarshen abin nadi da ƙirar zobe ya fi tsanani.

The toothed tsagi irin matsa lamba nadi tare da gefen sealed yafi dace da samar da ruwa kayan. Kayan ruwa sun fi saurin zamewa yayin extrusion. Saboda hatimin gefen gefen biyu na tsagi mai haƙori, ba shi da sauƙin zamewa zuwa ɓangarorin biyu yayin fitar da abinci, yana haifar da rarraba abinci iri ɗaya. Lalacewar abin nadi na matsa lamba da ƙirar zobe shima ya fi iri ɗaya, yana haifar da daidaiton tsayin pellet ɗin da aka samar.

Amfanin abin nadi na saƙar zuma shine cewa sawar ƙirar zobe ɗin daidai ce, kuma tsayin ɓangarorin da aka samar shima daidai yake. Duk da haka, aikin coil ba shi da kyau, wanda ke rinjayar fitarwa na granulator kuma ba shi da yawa kamar yadda ake amfani da nau'in ramuka a ainihin samarwa.

Mai zuwa takaice takaita guda 10 na mashin da ke motsa jiki a kan m zaren roller zobe, da na ƙarshe 3 tabbas waɗanda ba ku gani ba!

NO.10 Nau'in tsagi

NO.9 Rufe nau'in tsagi

NO.8 Nau'in zumar zuma

NO.7 Siffar lu'u-lu'u

NO.6 Tsagi mai karkata

NO.5 Tsagi+kan zuma

NO.4 Rufe tsagi+kakin zuma

NO.3 Madaidaicin tsagi+kan zuma

NO.2 Kashin kashin kifi

NO.1 Ripple mai siffar Arc

MISALI NA MUSAMMAN: TUNGSTEN CARBIDE COLLER SHELL

Hanyar magani don zamewar abin nadi na matsa lamba na injin barbashi

Saboda matsanancin yanayin aiki, ƙarfin aiki mai ƙarfi, da saurin lalacewa na harsashi na abin nadi, abin nadi yana da rauni na injin barbashi kuma yana buƙatar sauyawa akai-akai. Ayyukan samarwa sun nuna cewa idan dai halayen kayan aikin sun canza ko wasu yanayi sun canza yayin aiki, abin da ke faruwa na zamewa na nadi na matsa lamba na na'ura na iya faruwa. Idan akwai zamewar abin nadi a lokacin aikin granulation, don Allah kar a firgita. Don takamaiman bayani, da fatan za a koma zuwa fasaha masu zuwa:

Dalili na 1: Rashin matsuguni na abin nadi mai matsa lamba da shigarwar sandal

Magani:

Bincika idan shigar da matsi na nadi bearings yana da ma'ana don gujewa haifar da harsashin abin nadi don karkata zuwa gefe ɗaya.

Dalili na 2: Ƙararren bakin kararrawa na zobe yana ƙasa da ƙasa, yana haifar da rashin cin kayan aiki

Magani:

Bincika lalacewa na matsi, ƙafafun watsawa, da zoben rufi na granulator.

Daidaita maƙasudin shigarwar ƙirar zobe, tare da kuskuren da bai wuce 0.3mm ba.

Ya kamata a daidaita tazarar da ke tsakanin na'urorin matsa lamba zuwa: rabin aikin aikin na'urorin na'ura suna aiki tare da mold, kuma motar daidaitawa ta rata da kulle kulle ya kamata kuma a tabbatar da kasancewa cikin kyakkyawan yanayin aiki.

Lokacin da abin nadi ya zube, kar a bar na'urar ta yi aiki na dogon lokaci kuma jira ta fitar da kayan da kanta.

Matsakaicin matsi na buɗaɗɗen ƙirar zobe da aka yi amfani da shi ya yi tsayi da yawa, wanda ke haifar da juriya na fitarwa na kayan abu kuma yana ɗaya daga cikin dalilan zamewar abin nadi.

Kada a ƙyale injin pellet yayi aiki ba dole ba tare da ciyar da kayan aiki ba.

Dalili na 3: Matsakaicin abin nadi yana makale

Magani:

Maye gurbin matsi na abin nadi.

Dalili na 4: Harsashin abin nadi na matsin lamba ba ya zagaye

Magani:

Ingancin harsashin abin nadi bai cancanta ba, maye gurbin ko gyara harsashin abin nadi.

Lokacin da abin nadi na matsa lamba ya zame, yakamata a dakatar da shi a kan lokaci don guje wa tsawaita rashin aiki na abin nadi.

Dalili na 5: Lankwasawa ko sassauta matsi na abin nadi

Magani:

Sauya ko ƙara ƙarar sandar, da kuma duba yanayin matsi na abin nadi lokacin maye gurbin ƙirar zobe da abin nadi mai matsa lamba.

Dalili na 6: Wurin aiki na abin nadi na matsa lamba yana da ingantacciyar kuskure tare da saman aiki na ƙirar zobe (masu haye gefe)

Magani:

Bincika idan an shigar da abin nadi na matsa lamba ba daidai ba kuma musanya shi.

Bincika idan madaidaicin ramin matsi na abin nadi ya lalace.

Bincika don lalacewa a kan babban ramukan shaft ko bushings na na'urar barbashi.

Dalili na 7: Ƙaƙwalwar igiya na granulator ya yi girma da yawa

Magani:

Bincika ƙyalli mai ƙarfi na granulator.

Dalili na 8: Adadin naushi na ƙirar zobe yayi ƙasa (kasa da 98%)

Magani:

Yi amfani da rawar harbin bindiga don haƙa ta cikin ramin ƙura, ko tafasa shi da mai, niƙa kafin a ci abinci.

Dalili na 9: Kayan danye sun yi yawa kuma suna da yawan danshi

Magani:

Kula da kiyaye danshi na kusan 15%. Idan danshin kayan da ke cikin kayan ya yi yawa, za a sami toshewar ƙwayar cuta da zamewa bayan da albarkatun ƙasa sun shiga ƙirar zobe. Matsakaicin kula da danshi na albarkatun ƙasa shine tsakanin 13-20%.

Dalili na 10: Sabon mold ciyar da sauri

Magani:

Daidaita gudun don tabbatar da cewa abin nadi yana da isassun gogayya, hana abin nadi daga zamewa, kuma da sauri duba lalacewa na ƙirar zobe da abin nadi na matsa lamba.

Lokacin aikawa: Maris 25-2024